A Piece of the "Rock"

CRI&P Pacific 938

- by C. Kevin McCabe

Chicago, Rock Island & Pacific 938 was under steam for the very last time on September 16, 1953, just before proceeding to Chicago's LaSalle Street Station for a press announcement of Rock Island's attaining its 100% dieselization goal. The 938 had been specially painted and striped for the event. Later in the day, 938 returned to storage at Blue Island. The accession of 4-6-2 Pacific type locomotive 938 marks a significant milestone for the Museum's collection, as it represents one of the most common passenger-service wheel arrangements. Photo by R. W Buhrmaster.

In early May, 1995, the Museum purchased yet another "new" steam locomotive, Chicago, Rock Island & Pacific 938, a Pacific or 4-6-2.

The locomotive is significant to the Museum's collection in that it is the our first 4-6-2 type and our only Rock Island locomotive, filling two major gaps in our collection. Just as important, however, is the locomotive's strong historical connection to Chicago; Pacific 938 was the last Rock Island locomotive under steam on the railroad's official dieselization date, September 16, 1953. Employed to that date in commuter service, 938 may have been the last Rock Island steam locomotive in passenger service, since the railroad had previously dieselized its inter-city passenger service.

Pacific 938 was built in November 1910 by Alco's Schenectady Works as part of the Rock Island's first order for superheated Pacifies. With only 45 square feet of grate area and no stoker, the locomotive's steaming capacity could not keep up with the large 25" diameter cylinders. Though liners were later installed to reduce the cylinder diameters, many of these small Pacifics wound up in commuter service rather than mainline passenger assignments.

After retirement, 938 was displayed for many years in Enid, Oklahoma, at a state hospital. It was purchased by the Fort Worth & Western Railroad (AKA, the "Tarantula") and trucked to Fort Worth with the boiler separated from the frame.

The locomotive is in fair condition with all major appliances present (headlight, bell, whistle, air compressor, dynamo, etc.). The boiler is pitted and the firebox heavily patched, but a final determination of condition must await its arrival at the Museum. The tender has more than a few holes in it and one truck has an oak tree stump instead of springs, but there's nothing irreparable. Can she ever be made operational? We'll let you know as soon as a complete inspection is done.

The purchase price of the locomotive was $20,000 with approximately another $5,000 to $10,000 needed to move it to the Museum later this year. The immediate purchase was made possible by a generous short-term loan from a member but we must repay him within a year. So, Rock Island and steam fans, please unlimber those wallets once again and give us a hand. Please mark your checks "Rock Island 938."

A Complete and Authentic Train...

Rock Island Commuter Coaches

- by Greg Heier

The purchase of Chicago, Rock Island & Pacific 938, a 4-6-2 used in Joliet to Chicago commuter service, gives IRM its second complete, authentic train--a CRI&P suburban train of the early 1950s.

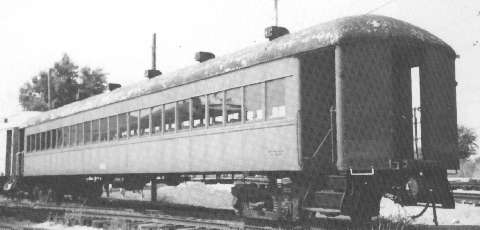

Rock Island Coach 2571 shows its lightweight designs. Photo by Greg Heier.

The first complete train, of course, is the Nebraska Zephyr trainset and Silver Pilot locomotive. The second, should it be possible to rebuild the 938 to operating condition, would consist of the 938 and our five Harriman-style, ex-Rock Island commuter coaches. Although we cannot document individual assignments, the coaches were in commuter pool service and undoubtedly were trained with the 938 on more than one occasion.

The oversized generator on the top of the 938 was the lighting generator for the commuter trains. Through trains cars were lighted by batteries that were charged by underfloor generators. The generators were powered from the inboard axles through belts. On commuter cars, however, the runs were fairly short, with frequent stops, and the batteries never got a chance to charge up. An auxiliary generator solved this problem.

The oversized generator on Chicago, Rock Island & Pacific 938 was used to provide lighting for the commuter coaches. Photo by R. W Buhrmaster.

The "Rock" coaches, however, are important to the Museum in another way--they can provide "seats" for our public. They are lightweight, high-capacity coaches with windows that open wide for excellent ventilation.

The big windows are real crowd pleasers, especially on days when the temperature tops 90. But, as the saying goes, "therein lies the rub." The window latches on the Rock Island coaches were worn out when they arrived at the Museum, and the windows either wouldn't stay open, or worse yet, would "self-close" without advance warning, which, of course, was very rude to our guests.

Several years ago we took the Rock Island coaches out of service pending replacement of the window latches. Roger Kramer did some research and found that new latches that would maintain the historicity of the cars were indeed available. Unfortunately, the purchase and installation of the latches would cost several thousand dollars per car, and this was money that was simply not available at the time.

During the last few years, some of the cars received interior and exterior painting, and seat cushion repairs and reupholstering, and more is needed. One of the coaches also needs about $3,000 in truck work. In all we need about $15,000 to get these cars rolling again, and with the greater length of IRM's demonstration railroad, it becomes imperative that these cars be returned to service.

We seldom think of commuter cars as being glamorous, especially when compared with the classic Pullman era, but utilitarian is an honorable trait.

Help us get these cars back on the line. Send your donation today.

Santa Fe 2903...

The War "Baby"

- by Greg Heier

Next time you visit Illinois Railway Museum take a walk back to "Steam Land" and look at our newest, and largest, steam locomotive. There she stands, Santa Fe 2903, one of the mighty giants that helped us win World War II a half century ago.

The 2903 was one of sixty-five 4-8-4 type steam locomotives owned by the Atchison, Topeka & Santa Fe Railway and used on its mainlines extending from Illinois to California. They were considered the backbone of the Santa Fe's fleet. Along with Milwaukee Road 265 and Grand Trunk Western 6323, it is the third 4-8-4 type locomotive in IRM's collection. But don't be tempted into calling it a "Northern" like you would for the previous two engines.

The 4-8-4 type received the nomenclature Northern because the first 4-8-4 was used on the Northern Pacific. A number of roads declined to use the name, such as the New York Central's Niagara and the Nashville, Chattanooga & St. Louis Dixie. On the Santa Fe, the official moniker was "Modified Mountain" (4-8-2 type locos were called Mountains). Similarly, the Santa Fe called its 4-6-4 locomotives "Modified Pacifies."

Santa Fe received its first 4-8-4 in 1927. It was the second railroad to order the wheel arrangement (after the Northern Pacific's ten 4-8-4s in 1926), and it was Baldwin's first 4-8-4. Between 1928 and 1941, thirty-five additional 4-8-4s were delivered to the Santa Fe, all built by the Baldwin Locomotive Company. The locomotives held down fast freight and passenger train runs across the system and on the flatlands a 4-8-4 could haul as many as twenty-nine heavyweight passenger cars.

With the outbreak of hostilities in 1941, the Santa Fe suddenly found itself without sufficient power for manifest freights and troop trains, not to mention the myriad other business increases caused by the war. With military production taking over most of America's manufacturing might, civilian auto and truck production came to a standstill and submarine and patrol boat production gobbled up diesel engine production capacity. The government established the War Production Board to ration manufacturing time and materials to where they would do the most good. Some railroads, such as the Chicago & North Western, were allotted diesel locomotives, while others, such as the Milwaukee Road, received new steam power. The Santa Fe received allotments for both steam and diesel power, ultimately receiving more than half of the EMD FT freight diesel production during the war.

Atchison, Topeka & Santa Fe 2903 ends a distinguished career as it enters retirement at Chicago's Museum of Science and Industry in 1961. The locomotive was donated to MSI and was moved to that museum through the use of panel track. Nearly a quarter of a century later, the locomotive would leave MSI over the reverse of the same route on its trek to IRM. Photo courtesy of Simmons-Boardman, 20th Century Railroad Club Collection.

Locomotive 2903 was one of thirty identical 4-8-4 type locomotives built for the Santa Fe by Baldwin in 1943 and 1944 for a cost of $252,335 each. Outwardly identical to the 1941 series (3776-3785), the 2900s were built with carbon steel boilers instead of nickel steel due to wartime restrictions. This made the 2900s the heaviest 4-8-4s ever built.

At full "fighting trim" (to use a most appropriate Navy term), 2903 tipped the scales at 975,400 pounds with a fully loaded tender. The locomotive alone weighed 510,150 pounds, with 293,860 pounds of that on the drivers, giving it a starting tractive force (at 66% cutoff) of 66,000 pounds, or a drawbar horsepower of almost 4,600 at 30 mph. Cylinder horsepower was rated at 5,600.

Like the earlier 3776 class 4-8-4s, the 2900s had 80" drivers with Walschaerts valve motion, driven by 28" diameter by 32" stroke pistons. The boiler pressure of 300 pounds per square inch was maintained by a boiler having an evaporative heating surface of 5312 square feet and a superheater heating surface of 2366 square feet. The 108 square foot grate area was one of the largest ever applied to a 4-8-4.

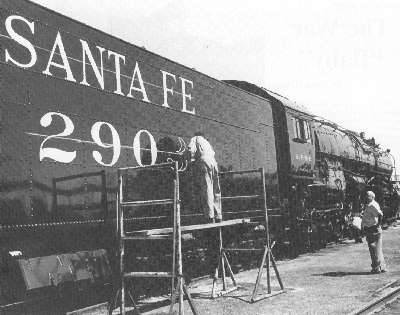

"Santa Fe steam locomotive 2903 is getting a fresh coat of paint at Clovis, New Mexico, prior to moving to Chicago for donation to the Museum of Science and Industry. It will be transported dead in train to Chicago after an exhibit site has been prepared, and will move down the bridle path paralleling the Outer Drive from 51st Street to the Museum. The move will be made by leapfrogging sections of rail around the engine as it goes forward, and will take two to three weeks. Santa Fe Railway News Bureau." So read the photo in the Chicago newspapers in 1961, when the engine was donated to MSI. Photo courtesy of Simmons-Boardman, 20th Century Railroad Club Collection.

The 2900s were immediately assigned to freight service on the Clovis, New Mexico, to Argentine, Kansas, Middle Division. Whereas the earlier 4-8-4s had been rated at 250 tons on the Middle Division grades, the 2900s were rated to 400 tons. On fast freights and passenger extras, the 2900s were allowed speeds up to their cross-balanced rating of 90 mph.

The 2900s quickly proved their worth with maintenance costs under $0.15 per mile as opposed to $0.29 per mile for other Santa Fe steam locomotives. Service availability was above average. With a water capacity of 24,500 gallons, and a fuel-oil capacity of 7,000 gallons, the locomotives could cover the division with fewer stops for servicing.

With WW II over, the 2903 remained in the Clovis-Argentine freight pool while some of the 1944 2900s were assigned to passenger service. All of the 2900s received Timken roller bearing side rods with needle bearings on the valve gear between 1946 and 1948, and Union Switch & Signal ATS (Automatic Train Stop) was installed in 1950. All but two of the 2900s also received either duplex siphons or (like 2903) security circulators by 1952, greatly improving steaming ability. As a result, the rated speed of the 2900 class was increased to 100 mph.

But even as improvements were being made on the 2900 class locomotives, the diesels were coming on fast. On December 30, 1953, the 2903 was moved from Argentine to Newton as a protection engine. On New Year's Day, 1954, the AT&SF was officially "totally dieselized." But management spoke, and decreasing numbers of the 2900s (and other classes) returned to steam for potato and wheat rushes in 1954 to 1956, and stood ready but not needed in 1957. The last 2900s were stricken from the roster in April 1959, after two years "stored serviceable" for grain rush calls that never came. Locomotives 2903, 2912, 2913, 2921, and 2926 were subsequently donated for exhibition in various cities, and 2925 eventually found itself at the California State Railway Museum.

Our engine, 2903, was donated to Chicago's Museum of Science and Industry, where it was to repose for a third of a century, almost three times as long as it was in service.

BIBLIOGRAPHY

Baldwin Locomotive Company official Builder's Photo, 1943

"Thirty Years of 4-8-4's" by Lloyd E. Stagner, Trains Magazine, February,

1987. Kalmbach Publishing Company, Milwaukee, Wisconsin.

Santa Fe 2903...

IRM's Biggest Challenge

- by Dan Paulissen

"How do you move a million-pound antique?" That was the question posed by the Chicago Tribune in an article about Santa Fe 2903 last Christmas Day. The story behind that question goes back a few years.

In 1993, Larry Goerges, at that time a member of IRM's Board of Directors, learned that Chicago's Museum of Science and Industry (MSI) was considering de-accessing Santa Fe 2903 from its collection. MSI's other outdoor rail equipment, New York Central 999 and the Pioneer Zephyr, were scheduled for restoration and inside display, but their 4-8-4 might need a new home.

After initial discussions with MSI, Larry turned the project over to Steam Department Curator Tom Schneider, who promptly drafted directors Kevin McCabe and Hugh Harris. Tom and Kevin met with MSI' s project resources director and other personnel, who confirmed that 2903 might be available. While they encouraged IRM to present a formal proposal (along with other interested museums and groups from as far away as Italy), they were clearly skeptical of our abilities.

There were many questions to be answered. MSI wanted to know in detail how the locomotive would be moved and how it would be displayed and interpreted. They also asked how funding for the movement would be assured. Answering those questions better than any other organization was the key to winning ownership of 2903. Besides that great prize, IRM would benefit from the likely press attention from such a move, and from the boost in status and reputation as a "can do" major museum. Before the "Steam Team" agreed to tackle the project and present a proposal, three big questions had to be answered. First, how were we going to raise funds in about a year's time? The Steam Department's initial rough estimate was $100,000 to $150,000 for the whole project. Second, how were we going to move it from MSI to the nearest railroad? Third, could the locomotive cross the bridge over the Fox River in Elgin? This locomotive is far from being light. It weighs over 660,000 pounds, engine and tender, empty.

How were we going to raise funds for this move? This question took a lot of serious thought. Early on, MSI asked us not to publicize 2903's availability; later, after 2903's availability had been announced, we could not assure donors that we would in fact get ownership. These restrictions severely hampered our fund-raising efforts. With the estimated project cost between $100,000 and $150,000, Tom, Hugh, and Kevin went hunting for money from a variety of sources. Tom was successful very quickly, with two $ 10,000 grants from corporations. Hugh sent out dozens of letters and grant applications, and also applied for a matching grant from the Illinois Department of Tourism. He too was successful, obtaining a $40,000 matching grant from the State of Illinois, the largest then available. Kevin concentrated on fund-raising from IRM's current and former members, donors, and supporters, along with companies in the railroad industry, using both mass mailing, hundreds of individual letters, and phone calls. By the end of 1994, we had raised over $80,000, with an additional $30,000 added over the following months.

The question of how to move the locomotive was initially the toughest. In 1961, the loco moved to MSI on panel tracks, leaving the Illinois Central near 47th Street. It would be a daunting task to retrace that path (now partially blocked by high-rises), so we sought other options.

The first alternative was to move the locomotive by barge just as MSI had recently moved its United 727. We contacted the same barge company, which said that 2903's size and weight wouldn't be a problem. However, we would need to dredge the lake shore to get the barge close to land, and build a massive ramp to bridge the gap between barge and shore. Once we learned that there was no place closer than Milwaukee to unload the barge at track level, that option was abandoned.

A second idea was to truck the locomotive to the IC, much the same way Southern Pacific 975 was moved in Beaumont, Texas. A heavy equipment hauler was contacted and submitted a quote for $50,000. However, there was a catch: The price did not include loading and unloading the locomotive. Once we learned that 2903's immense weight would require construction of a special rigging apparatus costing at least $100,000, this option too was discarded. We also decided not to try trucking the boiler and frame separately. While the cost would be considerably less, the work involved in removing the boiler and then re-assembling the locomotive at IRM was beyond our limited manpower.

Santa Fe 2903 "speeds" along toward the Museum of Science and Industry on November 25, 1961. In the next two decades, thousands of visitors would call on the big 4-8-4, before the exhibit was closed in 1994. Photo by Frank Spofford.

That left only the most basic means of movement, using 2903's own wheels on temporary track panels. Since the Illinois Central was the only nearby railroad, we needed their cooperation and assistance. Kevin contacted IC's president and received a very favorable reply. The railroad gave permission to use their line, and agreed to cut their main line to connect to our panel track. Now all we needed to find was a way to reach the railroad.

Throughout the Hyde Park neighborhood, the IC is elevated on an embankment. The nearest ground-level access to the south is at 71st Street; to the north, there was nothing before 47th Street. But Tom knew there was a ramp: the roadbed of an old team track, running down from the embankment to street level at Hyde Park Boulevard (51 st Street), was still used by the IC for vehicle access to track level. The railroad had owned the roadway for decades, but sold it while we were planning the project. If we could get permission from the new owners, though, it would work.

The 71st Street option was the longer route. The engine would need to move around the front of MSI (there wasn't enough room in back, due to a lagoon), through a heavily wooded park area, then down Stoney Island for fourteen long blocks. Traffic on Stoney Island and at the major intersection with 71st (where we would need to turn 90° onto the IC's tracks) might be disrupted for two weeks or more, which the city would not appreciate.

The Hyde Park option, though more congested in places, was only half as long. The engine would head north from MSI, cross 57th Street to a bridle path paralleling Lake Shore Drive until about 52nd Street, then curve to the northwest across a park to Hyde Park Boulevard. The locomotive would continue down Hyde Park (about two long blocks) until it reached the ramp just past Cornell Street. The toughest part would be two 90° turns onto and off of Hyde Park. This route was the most attractive option for us to pursue, for several reasons. First, this route had the shortest distance to lay panel track. Second, there was a cinder bridle path starting at 57th Street that would provide steady ground for 2903 to roll over. This path would also give us high visibility for publicity purposes. Third, we would not be blocking or riding on major streets, as most of the route would be on the bridle path or in a park. We expected to tie up Hyde Park for only a day. Finally, there were fewer trees in the way that we would have to remove or trim. Two contractors checked the route and confirmed they could handle it. The low bid was submitted by R.J. Corman, who estimated that they could do the job in five to six days for a firm price of $50,000.

Concerned that 2903 might be too heavy for the C&NW's Fox River bridge at Elgin, IRM General Manager Nick Kallas sent the C&NW the locomotive's specifications. The C&NW determined that the bridge and route were safe. Getting to the C&NW was another problem. Since 2903 could not make the turn onto IC' s St. Charles Air Line near the Loop, the route between the IC and the C&NW would have to be the long way around. to the south. Tom began making arrangements with the Belt Railway and the Indiana Harbor Belt to also transport 2903.

Once the method, route, and fund-raising issues were decided, Kevin spent many weeks preparing our formal proposal to MSI, with considerable input from Tom and Hugh. MSI was very impressed with our proposal's scope and detail, finally resulting in a favorable recommendation from MSI's staff at the end of last summer. MSI's Collections Committee concurred in November, sending their recommendation to MSI's Board of Directors. MSI's Board of Directors approved the transfer of ownership on December 14, 1994. Santa Fe 2903 was ours!

Both Kevin and Tom had already spent countless hours dealing with aldermen, park of finials, street department personnel, police, local citizens' groups, park activists, private landowners, insurance brokers, and many others whose opposition could have sunk the project at any point. With ownership of 2903 now assured, they redoubled their efforts to get the necessary permits, approvals, and agreements. The process literally took until the last moment, with the park district permit arriving by fax minutes before 2903 began moving.

Tom and project mechanical officer Bill Fogelis had inspected 2903 numerous times, but were unable to start mechanical preparations until the loco was ours. Fortunately, 2903 was in exceptionally good shape for a "park engine," far better than most we have obtained over the years. Almost all components except for the whistle and builder's plates were still present, even down to the sand scoop on the tender. The cab interior was 99% intact, with all valves, brake stand components, gauges, and other parts in place. All loco and tender roller bearings were still sealed and full of oil. We did have problems with MSI's modifications, including a mutilated spring hanger and cut brake rods, but Bill and the rest of the "Steam Team's" mechanical people did the impossible (as usual).

IRM is now the proud owner of "one big chooch," as Kevin described it to the Chicago Tribune. The project could not have been successful without the hundreds of hours of preparation, planning, and fundraising by Tom, Hugh, and Kevin, along with the efforts of the entire Steam Team. Because of their dedication to the success of IRM's largest-ever project, we obtained another "crown jewel" for our collection to be enjoyed by our visitors for many years to come.

In a future issue of Rail & Wire we'll tell the story of moving the 2903.

Look up, It's a...

New Ceiling for NSL 749

- Update Spring 1995 by Roger Hewett

Major restoration work of an artifact the size of Pullman-built North Shore coach 749 is done in a series of small steps—although, sometimes they're not so small! The NSL 749 Project passed two milestones in the winter of 1994-5, with the completion of two major projects—finishing car-body welding (except for closing in the No. 2 end anticlimber) and having the white, upper-interior ceiling professionally painted. These were both critical steps in our restoration schedule.

One of the major jobs in the restoration of North Shore Line 749, was the stripping and repainting of the interior ceiling. It looks pretty good with vent plates up and masking off. The restored bulls-eye lights were reinstalled to finish the ceiling. Photo by Roger Hewett.

Spring 1995 progress has been confined to lights, windows, left-side coach interior woodwork and the removal, stripping and reinstallation of the curved ceiling.

Last summer, after our 749 report went to press [Rail & Wire, September, 1994], IRM member Fred Perry, who hails from Maine (and the Seashore Trolley Museum), came out to do major metal work on the exterior of the No. l end (the designated "front" end). Fred cut away what was left of rusted subflooring and welded in new cross-member supports to hold-up the circle iron that supports the radial draft gear. Amazingly, this is what the North Shore Line did earlier to the No. 2 end. why the North Shore didn't do the No. 1 end at the same time is a mystery because the car was in danger of dropping its draft gear and causing a serious accident during its later years of operation.

With the lower area cleared, Fred welded in new steel under-flooring from inside the cab, out the train-door corridor, to either side of the outside doorway, and above the anticlimber. At the same time, he closed the anticlimber gap (caused by wreck or jarring hard coupling?) by lifting the anticlimber with hydraulic jacks and welding the gap shut. The window sills and drip rail over the windows on the left side (but not the right) had seriously rusted and Fred repaired these as well. Boy, do we ever appreciate Fred's welding skills!

Meanwhile inside the car, Ed Oslowski, in his protective garb, continued removing the old paint from the ceiling with triple-strength industrial grade paint remover. This was a long tedious job, taking most of the year. By September 4, 1994, Ed was clearly winning the battle of removing this stubborn paint. With several panels and some woodwork adjoining the ceiling left to do, his paint removal revealed North Shore's inconsistent placing of interior numerals during successive paint jobs. The last numerals "749" were placed lower and much to the left of earlier numbers. Evidently, they weren't finicky.

Elsewhere inside the car, Jay Cunnington and Roger Hewett temporarily reinstalled the baggage racks to mark the clearance holes in the new paneling. This was preparatory to removal and (later) painting of racks, paneling, and window woodwork stripped earlier in the shop. Afterwards, talented and hard-working volunteer Ray Bellock joined the NSL 749 restoration family. This was a blessing because Jay Cunnington later left the area again leaving us with only two consistent workers (less travels, vacations and hospitalization, of course).

On November 20th, we reviewed the remaining work to be done before our hired professional painter arrived. We were joined by Jay Ulloth and Joel Ahrendt, both of whom helped out restoring 749 from time to time. Ed Oslowski, who had finished stripping the ceiling and was scheduled for a second hip replacement, would not return until April. Afterwards, we all pitched in removing bulls-eye lights and stuffing their wire terminals into bags taped shut and pushing these up into the ceiling to avoid the paint damage. Of course, the trolley poles were tied down and the trolley rope was secured to the car top. The knife switch was turned down to disconnect the third rail-pickup, the light switches were turned off, and the switch cabinet was redtagged (danger), to warn all except Roger Hewett against opening. With flood lights ablaze, we then cleared the ceiling and gave it a final cleaning. After that it was bench work and awaiting a paint schedule.

Restoring the bulls-eye lights was a much bigger job than we first thought—it took weeks. Ray Bellock and his son Steve removed years of grime; giving the covers and rims a good wash with tubs and running water. Vic Benning, Joel Ahrendt, Jay Cunnington, Jay Ulloth, Ray Bellock, Roger Hewett, and Department Curator Bob Bruneau, at different times, helped finish the task. By then, winter arrived so we had to wire up space heaters in the 749. We masked the ceiling from the rest of the car, and we were ready for the painter.

The big day arrived, December 6, 1994, marking the culmination of Ed Oslowski's work stripping paint. Mike Furst, of 1st Brothers Decorating Inc., sprayed heavy zinc primer onto our bare and receptive ceiling. We had prepared the car by blocking vents and heating with space heaters and lights for two days prior to any painting, to get ceiling metal (both sides) up to stable ambient temperatures in the 60s—and for a day after to insure a full paint cure. Outside temperatures were in the low 20s at night and around 32 degrees for daytime highs. A week later, Mike returned to put on the final coats using electric attraction of the paint molecules to ensure evenness. The vent plates, under the covers and spacers. had to be painted too, of course, so Mike did them outside of the car and then hung them on the baggage racks in the heat to dry. With vent covers reinstalled, masking removed, and a final vacuuming by Ray Bellock to pretty up the old gal, that part of the job was finished—our Christmas present—as of December 17, 1994.

Dan Gornstein secured a donation of new cork gaskets (replacing asbestos). so Ray and I remounted the lights and put in the bulbs. Finally, three months to the day, we put the trolley pole up again.

North Shore 749 is presently the lead car on the middle track of Barn 4 still in faded "as received economy green." Next, we'll repaint the exterior. Why not stop by and take a look?

Look Out and Light Up...

Restoration on the Inglehome - part 1

- By Roger Kramer and Bob Hunter

During its lifetime, the Pullman observation-sleeper Inglehome received a lot of hard service, first as the Inglehome, and later as the Illini Railroad Club's Chief Illini. While the car was repainted from its gaudy orange, blue, and silver Chief Illini colors back to Pullman Green some years ago, now the Steam Coach Department is undertaking a more comprehensive restoration.

Bill O'Brien started the project in 1991 when he started repairing the wood window frames, which were badly rotted. Removal of some of the windows revealed nine window frames and sills in various forms of rusted deterioration. The rusted steel portions would have to be removed, new pieces made to the same size and style, then shaped and fitted individually into each window frame. For a while, the project languished as other, more pressing projects were handled, and as funds were accumulated for the project, but fall and winter, 1993, found the Inglehome in the hands of Bob Hunter who continued the restoration efforts.

First, we had to find somebody to fabricate the parts needed, and to do the job right, the first time. Bill Frejd, owner of R&B Metal Products, Inc., of Woodstock, Illinois, graciously accepted the challenge and started making all kinds of parts for the Inglehome. It probably helped that he also likes trains.

Hunter and Bill O'Brien, along with Roger Kramer and Museum General Manager Nick Kallas, decided to again hire Louis Rowe of Rowe Welding of Belvidere, Illinois, to install and weld the new pieces into place. His expertise and fine work were proven on the North Shore Electroliner project in 1990.

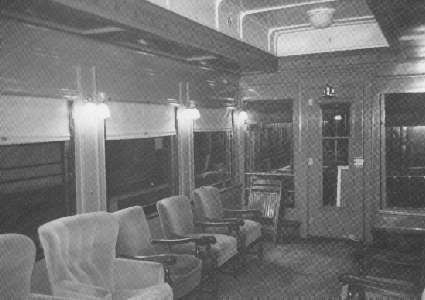

April 1995 finds the windows replaced, the intereior refurbished, and the lights working, giving us a glimpse of the luxury that was Pullman in its prime. Photo by Bob Hunter.

Welding started in late fall 1993 after a September of grinding and taking apart the metal around each frame. Louis Rowe brought out a portable oxyacetylene cutting torch and metal work table. These were all the tools he needed for this complicated job.

Each window frame was custom fitted. Each part that R&B Metal made had to be cut to the proper length, custom fitted and welded into place. Next, all exterior welds had to be ground flush with existing body trim. Then and only then was a coat of spray primer applied to the uncoated steel to preserve and protect the metal. This was repeated eleven times for the eleven windows that had to be repaired.

Winter soon approached cutting short this work. This was just as well because we had run out of money to pay Louis for further welding. We didn't want to have too big of an outstanding debt to pay next year. So even through there is more welding and fitting to complete on the Inglehome, weather and lack of funds brought welding to a halt.

Restoration slowed down but did not stop. Bob Hunter now devoted his attention to the arduous task of fitting window frames on the Inglehome.

Each window first had to be fitted into place. Then trim pieces had to be redrilled, holes retapped for 8-32 slotted oval head brass machine screws. Even to do that, each window frame takes from 15 to 20 holes. Each day there was time to do one window opening. And these heavyweight Pullman cars generally had an exterior and interior window for each opening. It takes a lot of time to complete one window opening.

During this time, Roger Kramer took time to study more about the electrical system of these old Pullman cars, with the hope of getting the car's 32-volt DC system working once again. In the spring of 1994, he inspected, cleaned, and installed a 28-cell set of Edison nickel-iron batteries. Upon connecting the battery charger especially built for 32-volt railroad batteries, he discovered that, indeed, the batteries were charging. He went into the car, threw the knife switch, and the Inglehome was transformed into the lighting wonderland it was intended to be.

The sleeper section of the Inglehome has open-section accommodations typical of the 1911 era. Photo by Bob Hunter.

In May of 1995, Mike Adams and Roger Kramer continued to check out the electrical system. They began by looking at the Vapor AC control system. Mike found some fuses, screwed them into their sockets and activated the controls. The relays clicked in, but nothing happened. They opened the ceiling access panel to get at the car's air conditioning blower motor. When they rotated the armature and repeated the process to activate relays, the blower motor started rotating. To say they were thrilled, would be an understatement.

As dust billowed out of the air duct, they had to wonder when the last time that blower operated. Mike and Roger called Bob Hunter over to the Inglehome. He was elated that the blower worked, but then laughed when he saw the dust floating around—another job to clean up!

Why not stop in and visit the Inglehome. Ask one of the workers for a tour. Oh yes, funds are still needed to install the traps and repair the roof before the final coat of paint can be applied. Anyone have an extra $10,000 to help finish the project? No? Well, small donations do add up.

Let There be Light

The early fall months of 1994 found us again tracing wires and non operating circuits on the Inglehome. We had separate light fixtures in the men's saloon that did not operate. I traced some wires, checked fuses. Everything seemed fine. How come they didn't work? There was also a light fixture in the hall that did not work. was it a separate circuit?

Without a wiring diagram, I just had to think how and where the wires were connected. Driving home, one evening, I recalled that in the women's saloon, there was a three way rotary switch that turns on all the lights or just one at a time. My "idea light" went on; the rotary switch in the men's saloon must be broken.

On the next weekend, I took the Switch out of the wall, checked it and, sure enough, one of the blades on the switch was burned out. Consequently, the light did not get any electricity. I rewired the switch by by-passing that blade. Why? You can't buy switches like that anymore. Remember this Pullman was built in 1911. One can't go to an electrical supply house and buy one off the shelf. After rewiring it and securing it back into the wall, l turned the electricity back on, rotated the switch and, success, the lights worked. Nobody at IRM had seen that light on, ever. Wow! The light was probably last on when the Inglehome was being used in Pullman Company service.

Another light that was not operating was one in the hall. I finally unscrewed the light fixture, took it off the wall and I discovered that somehow, the wires had shorted and one had completely melted disconnecting the socket. I opened up an electrical access panel, pulled out all of the old wires, and rewired it with new wires. When I turned the switch—another light in operation. I also found out that the switch which operates the hall light also operates the light in the bathroom. I speculated that these lights were wired this way so a Pullman porter would know if the bathroom was occupied or not.

- Roger Kramer

Come on Out...

Help Increase Attendance

- by Robert D. Albertson

"I never knew you were out here..." We hear it all the time. There are seven million people living in the Chicago metropolitan area, but we're only drawing about 45,000 a year. So, we have a lot of potential if people just knew about us.

Public admissions fund a large part of the Museum's annual budget. For each of the past two seasons, our attendance figures have increased slightly, and we'd all like to see that happen again in the coming years. And with the help of our volunteers and members, we can make it happen.

Some of our members already help publicize the Museum, just by word of mouth. They just talk about the Museum with friends and relatives. Others spread the word at railroadiana and hobby shows, or help with the bus parade program. We do a limited amount of paid advertising and of course, we print and distribute our brochures and calendars annually.

IRM got some great press coverage at the beginning of 1995 when we moved Santa Fe 2903 to IRM from Chicago's Museum of Science and Industry. And we can build on this momentum. Here's a couple of ideas that all members can help with. First and foremost, tell a friend and then another. Word of mouth advertising is as good as it gets.

Second, be our "clipping service." Big companies hire clipping services to track advertising and publicity. We send press releases to the electronic and print media, primarily in Chicago area and within two to three hour drive from the Museum, coordinated with the scheduled event days at the Museum. The objective of these press releases is to reach the general public, not the railfan community. We don't see all the papers in the area or listen to or see every radio, cable or local television so we need feedback from our Chicagoland area members. If members could take a few minutes and write down the times and dates of radio and television coverage, or clip newspaper articles about the Museum and include the name of the newspaper and date, it will help us measure the effectiveness of our releases. Send this information to IRM Publicity, PO Box 427, Union, IL 60180.

Third, if your local paper is not including our press releases, giving us the name of the editor and mailing address will help us try to reach them.

Fourth, since our brochure is such a beauty, we'd like to ask that members who work in businesses that are willing and able, take and display IRM brochures at checkout counters.

Fifth, we could use good "publicity" pictures, black and white or color, to include in our print media press releases. Sending a picture increases our chance of inclusion and increases the chance that the public will see and read the press release. Please send pictures with your name, address and phone number to "IRM Publicity." We will return them all at the end of the season.

We have a few other publicity ideas and maybe some of you do too. We'd love to hear them. Remember, we're trying to maximize the response and minimize the cost.

A Stroll Down "Electric Avenue"

Electric Car Doings

- by Bob Kutella

As winter 1994-5 finally set in, a number of the projects requiring outdoor activities or which are temperature dependent (like painting) slowed down. But not so for IRM's intrepid traction volunteers who always find a way to continue the work.

CINCINNATI & LAKE ERIE 640

Cincinnati & Lake Erie 640 was, and will be again, an interurban express motor. It was used by the C&LE to haul trolley freight trailers across the sprawling system. Later it was converted to internal combustion by American Aggregates for use as a switch engine. This Cincinnati Car Company product took up residence over the Car Shop pit shortly after arrival at the Museum. Carmen Carl Illwitzer and Andy Sunderland, along with Electric Car Department Curator Bob Bruneau, worked to remove most of the diesel and generator equipment as the first step toward restoring the 640 to trolley operation. After the car was relocated to its assigned storage location in Barn Eight, Carl repaired the rusted-out steel sides by welding in new steel patches near the floor line.

MILWAUKEE ELECTRIC L-4

Work continued on another freight motor, steeple cab L-4 from The Milwaukee Electric Railway & Light Company ("TM" for short). Carl Illwitzer set up a small glass shop to cut 1/4" plate glass for new windows on this locomotive.

FT. WAYNE & WABASH VALLEY 504

A huge amount of work continues to be accomplished by master woodworker Glenn Guerra. Probably 95% of both sides and both ends have been replaced or rebuilt. This includes manufacturing a veneer press to create curved widow lintels for both ends and another press to create the curved-plywood interior ceiling panels. But, don't get this confused with the kind of plywood you might find at your local lumberyard. Glenn's using 1/16" and 1/8" Tulipwood veneers.

The focus of the work is gradually shifting to the interior of this beautiful car. The rear platform interior and roof framing is being replaced to its original configuration, and the rear bulkhead is being reinstalled.

Interior side truss planks have been obtained and are being fitted. These are massive southern yellow pine planks which are about 3" x 12" by 30' long! A lot of the interior wood trim pieces are being stripped by Walter Murphy to be ready to refinish and reinstall. New upper sash panels for the interior are being fabricated, later to be veneered with Honduran mahogany.

Mechanical work continues with Carl Illwitzer rebuilding truck bolsters with new center bearings and side bearing plates. Numerous tie rods, hooks, custom fasteners for the body work, patterns, and castings are being designed and installed. Carl's also doing engineering work for new wheels.

MILWAUKEE ELECTRIC D-16

The D-16 is a TMER&L trolley crane that the TM used for maintenance. Carl IIlwitzer recently "created" a cab door that had been missing for decades. This is probably the first time it had a door there since it left the Cold Spring Shops in Milwaukee in the early 1960's.

MILWAUKEE ELECTRIC E-58

TM interurban flat car E-58 had been modified by Wisconsin Electric with the addition of structural steel trussing to the car sides below the car floor to increase its loadbearing capacity. To restore it to its TM appearance, Carl Illwitzer used his everpopular acetylene "saw" (cutting torch) to remove the trussing. He also installed a new "circle iron" support for the radial coupler on the end where it had been missing.

CHICAGO SURFACE LINES 3142

Work continues on Chicago Surface Lines 3142, with interior work taking the lead during the winter months. The pile of completed rattan-covered seat backs grew steadily taller until all were finished. The upholstery workers continue adding rattan covering to the restored seat cushions. Four of the seat cushions are now done. Project Manager Frank Sirinek and the 3142 crew welcomed new volunteer John Csoka who joined regulars Steve Iverson, Paul Lewandowski, Ed Rosengren, Mike Stauber, Greg Stepanek, Frank Wischler, and some we probably missed.

McGEES CLOSET

No, McGees Closet wasn't another acquisition by the "Body Snatchers" (the guys who go out with big trucks to rescue old trolley bodies). Rather, it was housecleaning and moving time for much of the parts and equipment stored in Barn Two, which was recently converted to the Diesel Shop.

Recently, the Museum acquired a number of retired intermodal containers and installed them along the service road east of the Buildings and Grounds Garage. These are assigned as storage space for specific departments and projects. In December, truckloads of stuff were loaded for transfer to the new storage location. The new arrangement should provide better access to the parts and materials.

CHICAGO TRANSIT AUTHORITY 6461

Chicago Transit Authority 6461 is one of Chicago's famous 6000-series rapid transit cars. When we received it, the car was painted in the simplified white over dark green scheme. Pete Vesic stripped the unstable and deteriorated paint and painted one end and part of a side in the original cream and light green scheme. The orange and dark green striping will be applied when the entire car has been painted.

KANSAS CITY PUBLIC SERVICE 755

Kansas City Public Service car 755 is a standard street railway PCC car that we purchased third-hand. Eventually, we hope to restore it to Kansas City livery. In December this goal moved a step closer with arrival at Union of a truckload of parts. We obtained these in trade from the Mad River and NKP Railroad Museum in Bellview, Ohio. Included in this delivery was a pair of B-2 trucks with full profile railroad wheels, a motor-generator set and a set of seat frames for this car. The railroad wheels will allow the car to be used on our demonstration railway.

MISCELLANEOUS

Carl Illwitzer cleaned and repaired two air compressors that were recently acquired for replacement parts. They will be added to our supply of "spares."

LAKE SHORE ELECTRIC 810

Lake Shore Electric 810 is the carbody on blocks in the grassy area just south of Barn 4. A second new bolster has been completed for this car and all riveting and finish painting is complete, thanks to George Clark, Norm Krentel, and Dan Gornstein. This very impressive piece of work has now been lifted and bolted in place underneath the car body. A needle beam has been fabricated to allow installation of some truss rods to help support the body and hold it square.

CHICAGO SURFACE LINES 9020

Chicago surface Lines 9020 is trailer that IRM has owned for many years. It is housed in Barn 7 along with many of the other cars in our Chicago collection. Recently, it was cleared of all the parts stored inside, and most of the seats have been re-installed, making it more presentable and interesting for display.

CHICAGO, SOUTH SHORE & SOUTH BEND 19, 28, 40

Jerry Kosinski has been cosmetically restoring all South Shore Line 19, 28, and 40. He has painted the exterior of the doors and the grab irons. Now he is working on locating and reinstalling missing interior parts. Carl Illwitzer has replaced the glass in several broken windows.

MILWAUKEE ELECTRIC 972

Milwaukee Electric streetcar 972 was operable in IRM's early years. Now, Ken Tendick has been restoring the interior of the car. Currently, he is stripping, staining, and revarnishing the window post covers. Future plans include refinishing the remaining woodwork and repainting the ceiling. All of the folding doors are being trimmed, fitted, and lubricated to get them in better working order. Rich Block and Bob Heinlein did a lot of work rewiring the light circuits for this car.

CHICAGO RAPID TRANSIT 4290

Ed Waytula and Tim Peters have been working on the platform subflooring on Chicago Rapid Transit 4290. The old flooring was pulled up and a lot of the steel framing was repaired or replaced. Work went quickly with Ed welding in the new pieces as fast as Tim could cut and fit them. Bill Wulfert has been working on the removable parts, refinishing them in the shop paint room. The controllers were stripped and painted and the end door windows were reinstalled after they were restored. Bill has recently passed a milestone; he's just rebuilt his 35th third-rail beam (a wood beam that insulates the 3rd-rail pickup shoe).

MISCELLANEOUS CRT DOINGS

Rich Block has rebuilt one of the door engines on Chicago Rapid Transit 4410. Rich and Bob Heinlein have adjusted and tuned all the doors on CRT 4410 and 4412. There are now three designated storage containers for the Rapid Transit collection. Many of the parts previously stored in the cars, along many newly acquired parts and supplies, have been relocated to the containers.

CLEVELAND TRANSIT SYSTEM 4223

Cleveland Transit System 4223 is one of our PCC cars, but visitors may not have recognized it when it last operated at IRM as Toronto 4648 (ex-Shaker Heights 4648). There is extensive salt and corrosion damage to the car body and frame, but this is now being addressed through the very generous support of one of our donors. The car was located in Barn 8 for a while and this is where Jim Blower did a huge job stripping the exterior paint. Meanwhile, an outside welding contractor has been retained to fabricate and install new bolsters and underframe members, and to replace the bottom 10" of the sides. Because of the heavy work involved, the car has been relocated to Barn 2.

PACIFIC FRUIT EXPRESS REEFER 64328

No, PFE 64328 isn't a trolley, but the car department has worked closely with freight car curator Mike Adams. The car lettering has been worked out using old blueprints and photos. Patterns have been cut and dimensional data and other lettering is being applied to this classic reefer by Karen Waldeck and Bob Kutella.

CHICAGO AURORA & ELGIN 309

Jeff Obarek and John Houck just won't give up. Even in the cold and late afternoon near darkness of the coldest winter of the decade they were stretching, folding, and tacking new canvas on Chicago, Aurora & Elgin 309. Jeff said if it got much colder, he'd have to play some beach music instead of his vintage big band CD's and tell the rest of the crew to imagine it was 70 degrees outside.